2. Reversion

A single measurement can not reveal maladjustment presence. Nor do multiple measurements if incorrectly done. One potential way to determine if equipment error exists is by Reversion. Reversion is based on reversing the geometry of a particular instrument condition between repeated measurements. This has the effect of allowing us to see twice the error present in that condition.

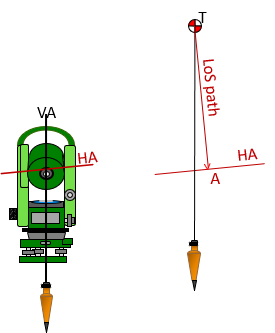

For example, Figure A-1 shows the effect of a Total Station Instrument (TSI) with a Horizontal Axis (HA) which is not perpendicular to its Vertical Axis (VA).

With the instrument set up and leveled, point T is sighted, and then the telescope is rotated to horizontal, Figure A-1a. The telescope, along with Line of Sight (LoS), is constrained to rotate about the HA. Because the HA is inclined up to the right, the LoS rotates to point A which is right of vertical.

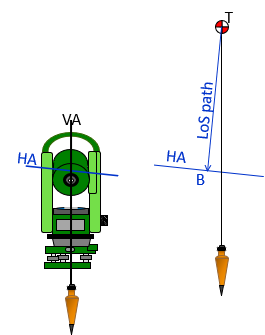

The instrument is rotated horizontally 180° which causes the HA to be inclined up to the left, opposite of the previous condition. Point T is sighted, the LoS is rotated to horizontal, winding up at point B, left of vertical, Figure A-1b.

|

|

| a. First pointing | b. Second pointing |

| Figure A-1 Horizontal Axis Maladjustment |

|

For each pointing, the angle between the LoS path and vertical is the amount the HA is inclined.

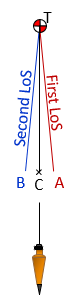

Figure A-2 shows both LoS paths superimposed.

|

| Figure A-2 Both Pointings |

Point C is vertically below point T and is located halfway between points A and B; the distance between points A and B is twice the HA error.

Once a maladjustment is identified, its effect can be compensated by procedure, adjustment, or computation. Because it can be compensated, an error revealed by reversion is systematic.

Reversion is an important concept because using it during measuring can automatically cancel some systematic instrumental errors. Learning a measurement science includes learning processes that minimize errors and provide them opportunity to compensate.

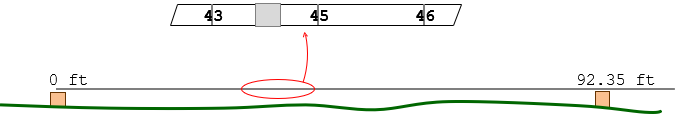

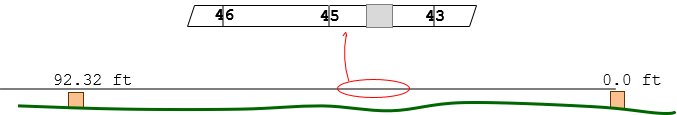

Reversion does not, however, work in all situations. Consider a repaired steel tape that has one foot removed between 43 and 45 feet. Measuring a line longer than 43 feet forward, Figure A-3a, and backward, Figure A3b, will always be one foot too long.

|

| a. Forward measurement |

|

| b. Reverse measurement |

| Figure A-3 Tape with Missing Foot |

Measuring a distance shorter than 43 feet will not be affected by the missing foot.

The missing foot is a systematic instrumental error but it cannot be compensated, nor revealed, by reversion.